Tackling a chimney project can feel overwhelming for many homeowners. The thought of cutting through your roof and ensuring everything stays watertight often causes anxiety. But what if you could approach this task with complete confidence?

This comprehensive guide breaks down the entire process into manageable steps. You’ll learn professional techniques that make the work straightforward and secure. Whether you’re adding a wood-burning stove or upgrading your current system, we’ve got you covered.

We’ll walk you through careful planning, proper tool selection, and creating durable seals. Our expert advice focuses on safety and longevity. You’ll discover how to achieve results that protect your home for years to come.

By following this guidance, you’ll save money while gaining valuable skills. The journey from initial preparation to final sealing becomes clear and achievable. Let’s transform that daunting project into a successful DIY accomplishment.

Introduction to Metal Chimney Installation

The prospect of creating an opening in your overhead structure for stove exhaust can cause hesitation. Many property owners worry about potential leaks and ensuring a secure setup. However, with the right approach, this task becomes much more manageable.

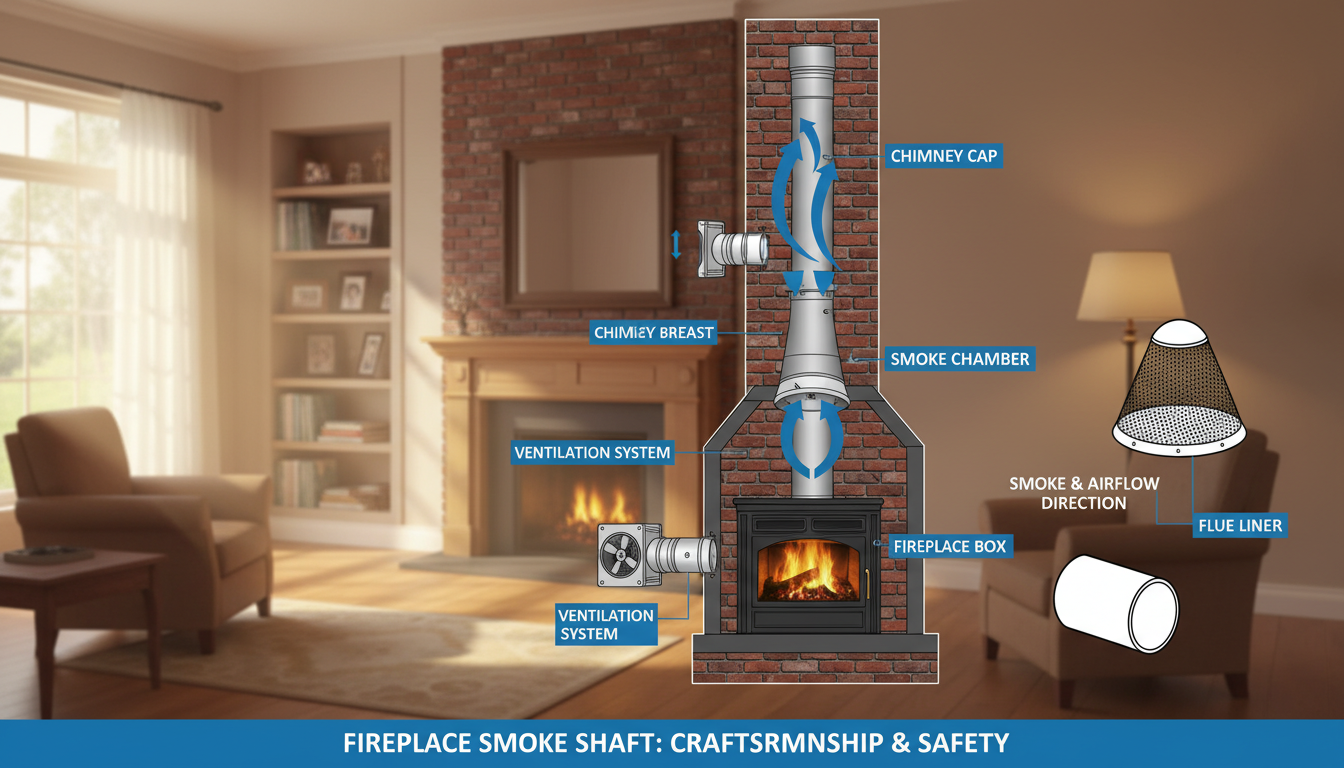

Adding a wood stove heating system has gained popularity for its flexibility and efficient venting solutions. Modern systems feature modular components designed specifically for homeowner projects. These pieces fit together systematically, creating a safe and effective exhaust pathway.

Success in this endeavor depends heavily on thorough preparation. Quality materials and adherence to safety guidelines are essential from start to finish. Proper planning ensures your heating appliance functions optimally while protecting your residence.

A correctly implemented vent system provides safe operation for your wood stove. It also safeguards your roof from water damage and maintains your home’s structural integrity. With clear understanding and the right methodology, you can approach this improvement with confidence.

This foundation sets the stage for detailed steps ahead, preparing you for a successful outcome.

Understanding Chimney Clearance and Safety Guidelines

The gap surrounding your venting system plays a crucial role in fire prevention. This space protects your home from heat transfer to combustible materials. Following proper guidelines ensures your heating appliance operates safely.

Importance of Adequate Clearance

Different stove pipe types require specific spacing. Single wall pipes need more room than insulated double or triple wall systems. Always check manufacturer specifications for your particular setup.

Most systems like Metal-Fab designs require at least 2 inches of clearance. This detail prevents heat from reaching wood framing and insulation. Proper spacing protects your investment in the heating system.

Fire Safety and Risk Prevention

Maintain clearance from the stove connection through the roof structure. This prevents dangerous heat buildup in confined spaces. Thermal expansion of metal components needs adequate room.

Expert advice emphasizes checking local building codes. Requirements vary by region and product type. Following these guidelines protects your family and home from fire risks.

The flue system must maintain consistent spacing throughout. Never compromise on clearance specifications. This approach ensures long-term safety for your wood stove operation.

Planning Your Metal Chimney Installation Project

A well-organized approach to your stove exhaust project begins with careful assessment of your specific situation. Taking adequate time for preparation prevents costly mistakes and ensures a smooth process from start to finish.

Assessing Your Roof Type and Materials

Your roof composition significantly impacts the installation approach. Metal roof surfaces present different challenges than traditional asphalt shingles.

Corrugated barn roofs require special attention to flashing seals. Manufacturers like Selkirk provide detailed guidance for various roof materials. Review their resources before purchasing components.

Examine your roof’s pitch and structural support system. This assessment determines what materials and support brackets you’ll need.

Gathering Necessary Tools and Materials

Having the right tools ready saves time and frustration. Essential equipment includes:

- Reciprocating saw for cutting metal surfaces

- Drill, measuring tape, and level

- Tin snips and caulking gun

- Proper safety gear

Material requirements include your complete chimney kit, appropriate flashing, high-temperature sealant, and storm collar. Allocate sufficient time for planning each step before beginning work.

Thorough preparation ensures your chimney functions safely for years to come.

Selecting the Right Chimney Kit for Your Stove

Your wood-burning appliance’s performance and safety depend heavily on choosing the correct exhaust components. The right stove chimney system ensures efficient operation while minimizing potential hazards. A mismatched setup can lead to poor draft and increased creosote buildup.

Matching your heating unit’s flue outlet is essential. Most systems require 14-inch diameter pipe sections. Smaller 30-inch fireplaces typically use 12-inch components. Always verify your specific requirements before purchasing.

Double-wall or twin-wall pipe designs offer superior safety features. The air-cooled construction keeps exterior surfaces cooler during operation. This design also accommodates natural expansion under high temperatures.

Quality kits from reputable manufacturers include all necessary parts. Look for complete systems with flashing, storm collar, and roof support brackets. UL-103 compliance ensures the system meets rigorous safety standards for residential use.

Stainless steel construction provides durability against high heat and weather exposure. Investing in a quality stove chimney kit delivers long-term reliability. Proper components work together for safe, efficient wood stove operation.

Metal Chimney Installation: Expert Tips for Success

The difference between a temporary fix and a permanent solution often comes down to preparation and patience. Many people successfully complete their own projects, saving around $1,800 while gaining valuable skills.

Professional installers emphasize that attention to detail separates mediocre work from flawless performance. Before installing chimney components, thoroughly research your specific system. Read manufacturer instructions and watch demonstration videos.

Take your time with each step rather than rushing. Most problems arise from hurrying through critical details. When you encounter uncertainty, don’t hesitate to seek advice from experienced sources.

Working methodically prevents common issues that could require costly repairs later. Consider making this a family project, turning work into quality time together. Document each step with photos for future reference.

Basic knowledge combined with careful execution will serve you well. This approach ensures your chimney functions safely for years to come.

Preparing Your Metal Roof for Chimney Installation

Getting your overhead surface ready requires careful attention to detail. This phase sets the foundation for everything that follows. Proper preparation prevents problems with alignment and weather protection.

Measuring and Marking the Roof Surface

Start by finding the exact spot where your pipe will pass through. Work from inside your home to establish a centerline from your stove upward. This ensures your exhaust pathway avoids structural supports.

Transfer this centerpoint to the top of your roof using a plumb bob or laser level. Take multiple measurements from different angles for accuracy. Mark cutting lines clearly on your metal roof panels.

When dealing with corrugated designs, plan placement to minimize ridge cutting. Remember the carpenter’s wisdom: measure twice, cut once. This approach prevents costly errors.

Choosing the Right Tools for Precision

Having proper equipment makes this section much smoother. Essential items include a quality reciprocating saw with metal-cutting blades. Sharp tin snips and a reliable measuring tape are equally important.

These tools help create clean cuts through your ceiling roof structure. They ensure your markings translate into precise openings. Good equipment contributes significantly to a professional outcome.

Investing in the right gear pays dividends throughout the project. It makes the work safer and more efficient. Your preparation now will show in the final results.

Cutting the Hole in Your Metal Roof

Creating the opening for your vent system might seem daunting, but with the right approach it becomes quite manageable. This crucial step establishes the pathway for your stove’s exhaust to safely exit your home.

Proper technique ensures clean results that will support your system for years. Taking your time here pays dividends throughout the entire project.

Step-by-Step Cutting Process

Begin by drilling a small pilot hole at your marked center point. This gives your saw blade a clean entry and prevents the material from grabbing unexpectedly.

A reciprocating saw with metal-cutting blades works perfectly for this task. Move steadily around your marked circle, letting the tool do the work without forcing it.

Be mindful of the ceiling structure below as you cut. You want to remove only the roof panels without damaging any supporting elements.

For corrugated surfaces, tin snips help with fine adjustments in tight spaces. Once complete, smooth all edges with a file to prevent injuries.

Inspect your opening from both above and below. Ensure you’ve maintained proper clearances and haven’t compromised any structural components.

Finally, clean up all metal shavings thoroughly. This keeps your work area safe and prepares you for the next phase of your project.

Installing Flashing for a Watertight Seal

The flashing component serves as your primary defense against water intrusion where the pipe meets the roof surface. This critical piece prevents costly water damage by creating an impenetrable barrier against rain and moisture.

Without proper flashing, rainwater can seep into tiny gaps around your vent pipe. This leads to expensive repairs and potential structural issues. Getting this step right protects your investment for years to come.

Choosing the Correct Flashing Material

Selecting the right flashing material depends on your specific roof type. Flat surfaces need different solutions than corrugated designs. The wrong choice can compromise your entire system’s effectiveness.

For metal roof applications, look for adjustable flashing that conforms to panel contours. Quality materials withstand weather exposure while maintaining their protective seal. Always match your flashing to your roof’s profile for optimal performance.

Proper Installation Techniques

Begin by sliding the flashing over the top of your pipe. Position it flat against the roof surface, ensuring complete contact. This creates the foundation for your watertight barrier.

Secure the flashing with appropriate screws designed for metal surfaces. Apply high-quality sealant under the edges before fastening. Add additional sealant around the perimeter for complete protection.

Finally, inspect your work from the top to verify water will flow naturally away from the penetration. Proper installation ensures your flashing directs moisture safely down the roof surface.

Positioning and Securing the Chimney Pipe

A stable chimney pipe is the backbone of a safe and efficient wood stove system. Getting this step right ensures optimal draft while preventing dangerous movement. Your careful work here protects your home for years.

Begin from your wood stove connection point. Work upward through the ceiling opening with perfect vertical alignment. This straight path maintains critical clearances from all sides.

Aligning the Stove Pipe Accurately

Your stove pipe must pass through the ceiling roof at the proper angle. Typically, this means straight vertical alignment. This positioning keeps adequate space from flammable materials.

Use the support collar included in your kit at the ceiling penetration. This component strengthens the setup significantly. It prevents unwanted shifting that could compromise safety.

Roof Support Bracket Installation

Bracket installation stabilizes the pipe where it exits through the roof surface. Secure brackets tightly around the pipe’s exterior. Fasten them to structural members rather than just the roof surface.

As you stack pipe sections upward, ensure each connection locks properly. The top should extend 2-3 feet above your roof peak. This height ensures adequate draft in windy conditions.

Double-check that your completed installation remains perfectly vertical. A well-secured pipe provides peace of mind for years of reliable operation.

Ensuring Proper Chimney Pipe Ventilation

Effective ventilation within your exhaust system is the cornerstone of safe wood stove operation. Proper airflow ensures harmful gases escape efficiently while maintaining optimal performance. This critical function protects your home from dangerous carbon monoxide buildup.

Your flue system must allow heated gases to rise freely through the chimney pipe. This creates natural draft that pulls combustion air into your stove. Unobstructed airflow is essential for removing smoke and byproducts outdoors.

Double wall pipe construction offers superior ventilation characteristics. The air-cooled design maintains proper clearances while allowing the inner wall to reach optimal temperatures. This setup provides enhanced safety and performance for your heating appliance.

Proper ventilation requires your pipe to extend high enough above the roof. This prevents downdrafts from nearby trees or building structures. Adequate height ensures consistent draft in various weather conditions.

Never restrict air circulation around your chimney pipe. The designed ventilation space serves both safety and efficiency purposes. Ensure all connections remain properly sealed to prevent gas leakage between walls.

Sealing Around the Chimney to Prevent Leaks

Quality sealing techniques provide the ultimate safeguard against water damage where your exhaust system meets the roof. This critical step ensures your hard work pays off with long-lasting protection.

Using High-Quality Sealant Methods

After positioning your flashing, apply a generous bead of high-temperature silicone around the pipe. This creates a flexible barrier that expands and contracts with temperature changes.

Make sure to choose sealant rated for outdoor exposure and heat resistance. Standard caulk cannot withstand the conditions around a chimney pipe. Proper application prevents the most common leak problem homeowners face.

Effective Storm Collar Installation

The storm collar adds crucial secondary protection. Slide it down over the top of your pipe until it overlaps the flashing by an inch or two.

Tighten the adjustment band securely, then seal the top edge where it meets the pipe. This double-layer approach directs water safely away from your roof penetration.

Inspect all seals from both the roof top and inside your attic. Look for any gaps where water could infiltrate during heavy rain. Thorough sealing ensures your system remains watertight for years.

Compliance with Local Building Codes and Safety Standards

Navigating building regulations might seem like extra paperwork, but it’s your project’s safety net. These rules exist to protect your property and family from potential hazards. Understanding them upfront saves headaches later.

Understanding Regional Regulations

Requirements vary significantly between locations. Some areas demand permits and inspections for any vent system work. Others have specific clearance specifications that differ from national standards.

Contact your local building department before starting. They’ll explain permit requirements and inspection schedules for your house. This proactive approach prevents costly corrections later.

Many insurance company policies require code compliance. Failure to meet standards could void coverage if incidents occur. Proper documentation protects your investment.

Creating a Compliance Checklist

Build a simple checklist based on local codes. Include critical details like clearance distances and proper height requirements. This roadmap ensures you meet every specification.

Most jurisdictions focus on clearances to combustibles and flashing quality. Document how your work meets each requirement. Keep photos and product specifications organized.

Some people skip permits to save time or money. This often creates problems when selling their home or filing claims. Working with inspectors provides valuable guidance instead of obstacles.

Store all paperwork safely with your home records. This includes permits, inspection reports, and installation photos. Thorough documentation gives peace of mind for years.

Maintenance Tips for Long-Term Chimney Performance

Your new heating system deserves regular attention to maintain peak performance. Consistent care ensures safe operation and extends your investment’s lifespan significantly.

A well-maintained setup serves your home reliably for decades. Neglected systems become fire hazards that compromise safety.

Annual Inspection and Cleaning Routines

Annual cleaning is essential when burning wood. Creosote and soot accumulate in the flue throughout the heating season. This buildup can ignite if allowed to accumulate excessively.

Plan to clean your stove chimney at least once per year. More frequent cleaning may be needed with regular wood use. Reduced draft performance signals it’s time for attention.

During inspections, check the entire system from stove connection to top chimney cap. Look for loose parts, connection cracks, or rust on components. Any deterioration requires immediate attention.

The chimney cap deserves special focus. Ensure it remains securely attached and undamaged. This component prevents rain, snow, and debris from entering your flue.

Remove the cap periodically to inspect the top chimney opening. Check for creosote buildup or nesting materials that could restrict airflow. Blockages create dangerous conditions that affect performance.

Professional chimney sweeps offer specialized expertise. Hiring one every few years provides expert assessment of your system’s condition. They have tools for thorough cleaning that homeowners might lack.

Between professional services, monitor your wood stove’s operation closely. Excessive smoke or difficulty maintaining fires often indicates cleaning needs. Don’t wait until a full year has passed if performance declines.

Keep a maintenance log documenting inspection dates and activities. This valuable record helps track your chimney’s condition over time. Proper documentation gives peace of mind for years of safe operation.

Considering Time and Cost Factors for Your Installation

Many homeowners face important decisions about how to approach their heating system upgrade. Understanding the financial and time commitments helps determine the best path forward for your situation.

People who would like to save money can typically avoid $1,800 or more in professional labor costs. Tackling the project yourself with proper preparation offers significant savings. This approach also creates quality family time during the process.

The time investment ranges from a full weekend for experienced individuals to several weekends for newcomers. Beyond financial benefits, doing the work yourself ensures quality control. You maintain personal standards rather than depending on a contractor’s approach.

If you would like to hire professionals, get multiple quotes first. Verify that installers are licensed, insured, and experienced with your specific setup. Your insurance company may have requirements about who can perform this work.

Factor in all material costs including the vent kit, flashing, sealants, and safety equipment. Consider that people living in their home during the project will experience some disruption. Plan timing to minimize impact on daily routines.

The value of learning new skills often outweighs the time investment for many homeowners. The satisfaction of completing a major improvement yourself brings lasting rewards.

Conclusion

Completing your own vent system project brings both practical benefits and personal satisfaction that lasts for years. This guide has walked you through every critical phase—from initial planning to final sealing.

Make sure to prioritize safety above all else. Maintain proper clearances and follow manufacturer guidelines carefully. Your home and family deserve this protection.

The key to success lies in careful preparation and patience. Rushing any step of installing chimney systems can lead to problems later. Whether adding a wood stove for heating or ambiance, proper installation ensures safe operation.

Remember to maintain your system through regular inspections. Don’t hesitate to consult professionals if needed. Enjoy the warmth and comfort your new setup brings to your home for seasons to come.

0 Comments