Welcome to your complete guide on building a sturdy and safe chimney for your home. This article is designed to walk you through the entire process, from the very first planning stages all the way to the final checks.

Whether you’re a hands-on homeowner ready for a DIY challenge or you just want to understand what professionals do, we’ve got you covered. We’ll explain the key parts that make these structures so strong and long-lasting.

Getting the construction right is absolutely vital for your family’s safety. A properly built chimney protects your house from fire risks and dangerous gases. It also makes sure smoke vents away efficiently.

You’ll learn professional methods used by experienced masons. We cover material choices and the technical rules that ensure your project meets all safety codes. We break down complex ideas into simple, friendly steps.

By the end of this guide, you will have a solid understanding of what makes a chimney safe, efficient, and durable. This knowledge is valuable whether you’re starting a new project or checking an old one.

Introduction: The Importance of a Proper Chimney

Understanding chimney fundamentals helps homeowners appreciate their importance. These systems serve as vital safety features for any residence with heating appliances.

Overview of Chimney Benefits

A well-constructed chimney acts like your home’s respiratory system. It safely removes smoke and combustion gases from living areas.

The flue inside creates necessary draft for efficient operation. This ensures your heating appliances work at their best while reducing fire risks.

Beyond safety, these structures add significant value to your property. They provide functional heating and enhance your home’s character.

Why a Well-Built Chimney Matters

Quality construction prevents dangerous carbon monoxide buildup. It also protects against water damage and heat transfer to combustible materials.

A solid chimney structure withstands decades of weather exposure. Proper design balances traditional craftsmanship with modern safety codes.

Investing in correct construction avoids costly repairs down the road. It ensures peace of mind for years of safe, efficient operation.

Brick Chimney Installation

Creating a permanent ventilation system for your home involves specialized skills and careful material selection. This masonry work requires precise techniques that experienced professionals master through years of practice.

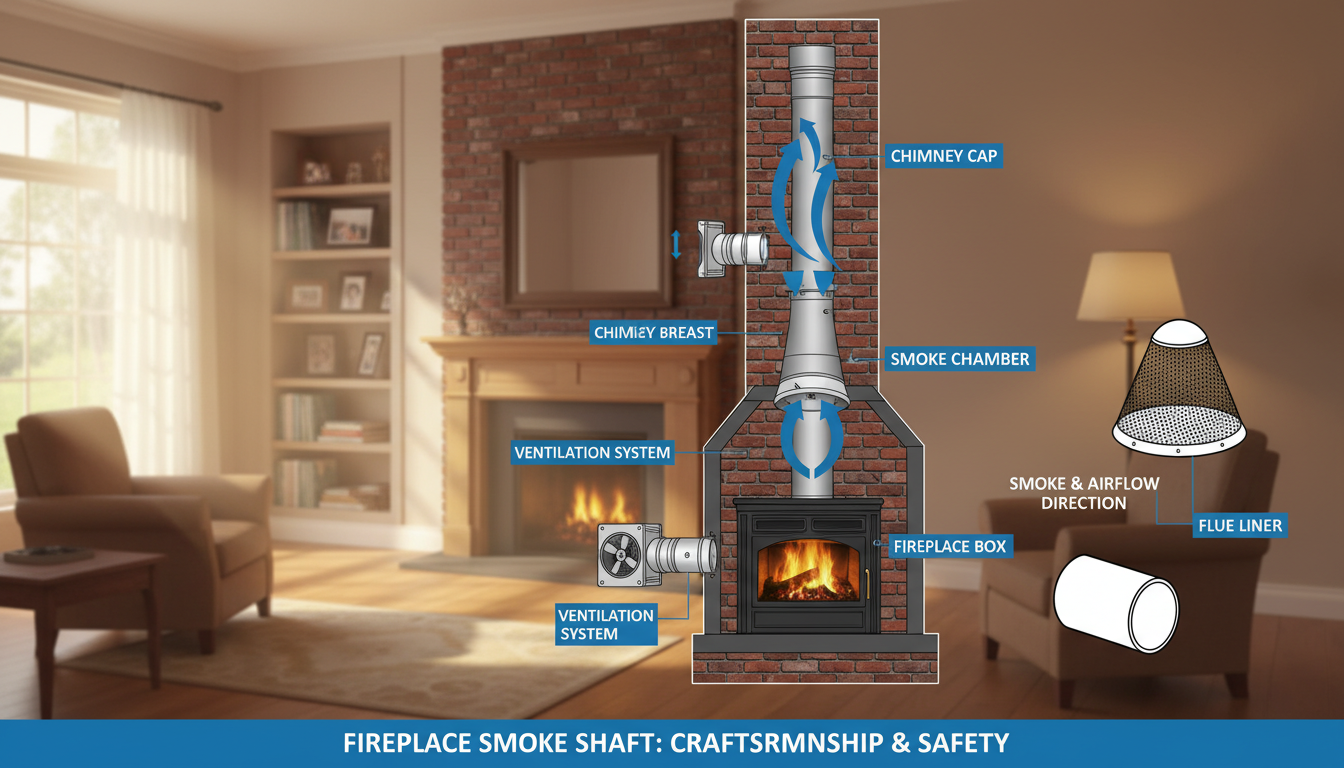

The construction follows a logical sequence where each phase builds upon the previous one. Foundation preparation comes first, followed by careful brick placement and flue liner integration. Proper capping completes the system.

Quality components must meet specific industry standards for heat resistance and durability. Using subpar materials compromises safety and reduces the structure’s lifespan significantly.

Understanding this complete process helps you make an informed choice about tackling the project yourself or hiring experts. Each decision affects the final outcome and long-term performance.

Throughout this guide, we’ll explore each phase in detail with practical tips for success. You’ll gain valuable insights whether you’re planning a DIY approach or working with professionals.

Planning Your Chimney Installation Project

Proper planning is the foundation of any successful chimney construction project. Taking time to prepare ensures your structure meets safety standards and functions efficiently for years.

Assessing Local Codes and Regulations

Before starting your building project, research local requirements thoroughly. Most areas follow the National Fire Protection Agency’s 211 standard. This includes specific height and clearance rules.

Your chimney must extend 3 feet above the roof penetration point. It needs to be 2 feet taller than any building part within 10 feet. These rules ensure proper draft and prevent downdrafts.

Clearance from combustible materials is critical. Allow 2 inches when building through walls. Maintain 1 inch when constructing alongside the house.

Project Planning Checklist

Create a detailed checklist for your construction job. Include material quantities, tool needs, and timeline estimates. Budget considerations keep the process organized.

Plan the foundation area carefully. The concrete footing must support the entire structure’s weight. Professional assessment is often recommended for this critical step.

Consider placement location for optimal draft efficiency. Avoid conflicts with existing structures. Determine which appliances the system will vent to guide flue sizing decisions.

Choosing Materials & Tools for Masonry Chimneys

The quality of your materials and tools directly impacts the longevity and safety of your masonry project. Making informed choices ensures your structure withstands weather and heat for decades.

Professional builders follow specific standards when selecting components. These guidelines help create durable, efficient systems that meet safety requirements.

Brick and Mortar Selection

Different brick types serve specific purposes in construction. Red clay and calcium silicate varieties offer excellent heat resistance and durability. They meet ASTM standards for weather performance.

For areas exposed to direct heat, fire brick provides superior protection. This specialized material handles thermal stress without deteriorating over time.

Mortar selection is equally critical. Standard mortar works for general bricklaying, while refractory mortar handles high-temperature applications. Each type has specific ASTM specifications for different uses.

Essential Tools and Supplies

Proper tools make masonry work more efficient and precise. Every builder needs these basic items:

- Quality trowels for mortar application

- Levels for straight, even courses

- Masonry saws for cutting materials

- Jointing tools for finishing work

Beyond tools, you’ll need flashing materials, concrete for foundations, and waterproof sealants. Understanding material applications helps balance cost and performance for your specific project.

Step-by-Step Construction Process

With proper preparation complete, the hands-on work begins as you assemble your ventilation system piece by piece. This phase requires careful attention to detail and consistent quality checks throughout.

Building a Solid Foundation

Start by preparing a perfectly level base for your masonry project. The reinforced concrete footing must extend below your area’s frost line to prevent settling.

Once the foundation cures, lay the first course to establish the structure’s footprint. This initial layer sets the alignment for all subsequent courses moving upward.

Laying Bricks with Proper Mortar Techniques

Mix your mortar to a thick peanut butter consistency that spreads easily but holds its shape. This provides strong bonds while allowing slight adjustments during placement.

Apply the mixture generously to each unit using a mason’s trowel. Proper application ensures mortar oozes slightly from joints, confirming complete filling between materials.

Continuously check both vertical and horizontal alignment as you build. Even small deviations can compound over height, potentially creating dangerous leaning.

Install flue tile liners by embedding them in refractory mortar with 1/16 to 1/8 inch joints. Maintain the proper air gap and ensure both components rise together in a coordinated way.

Installing Flue Liners, Caps, and Flashing

Properly finishing your masonry structure involves three critical elements that ensure long-term performance. These components protect against weather damage and maintain safe operation.

Flue Liner Installation Best Practices

Each flue section must align perfectly when embedded in refractory mortar. This creates a smooth interior surface that prevents dangerous creosote buildup.

Maintain the essential air gap between the liner and surrounding walls. This space allows for thermal expansion without cracking the structure.

Securing the Chimney Cap Correctly

The concrete cap should extend 1½ inches beyond the wall with a drip edge. Always include a bond break between the cap and flue top using flexible sealant.

This gap prevents liner damage during temperature changes. Proper slope directs water away from the opening.

Proper Flashing Techniques to Prevent Water Infiltration

Metal flashing creates waterproof barriers at roof intersections and under caps. Apply quality caulk underneath to seal against moisture.

This protection prevents costly water damage and maintains structural integrity for years of reliable service.

Ensuring Safety and Compliance

Navigating clearance requirements is crucial for creating a fire-safe chimney system that meets all regulations. These guidelines protect your home from potential hazards while ensuring optimal performance.

Clearance Guidelines from Combustible Materials

Maintaining proper air space between your chimney and surrounding materials is essential for fire prevention. Interior masonry chimneys need a minimum 2-inch clearance from any combustible wall or framing.

Exterior structures require at least 1 inch of space from flammable materials. The 12-inch rule allows materials to touch the outer wall if they stay 12 inches from the flue liner interior.

Special rules apply to fireplace mantels and trim. Combustible elements within 12 inches of the opening cannot project more than 1/8 inch per inch of distance.

Inspection and Code Compliance

Professional verification ensures your project meets current building standards. Inspections should occur at multiple stages during construction.

Proper flue size calculation is critical for safe operation. For fireplaces with 15-foot or taller chimneys, the flue cross-section must equal 1/10th of the fireplace opening area.

Different heating appliances have specific connection requirements. Always follow manufacturer specifications and local codes for furnace, wood stove, and gas appliance installations.

Final inspection confirms all clearances, materials, and construction techniques meet safety standards before use. This thorough approach guarantees years of reliable, compliant operation.

Common Challenges and Expert Solutions

Every chimney project presents unique obstacles that require practical solutions. Understanding these common issues helps you build a safer, more durable structure that stands the test of time.

Proper planning prevents many problems before they occur. Let’s explore the most frequent challenges and how to address them effectively.

Avoiding Installation Mistakes

Mortar consistency is crucial for strong masonry work. Too wet or too dry mixtures create weak bonds that lead to water infiltration and structural damage.

Foundation preparation cannot be rushed. The entire chimney depends on a solid, properly reinforced base. This critical part of construction prevents settling problems.

When dealing with angled flues, remember the 30-degree maximum rule. Offset sections need careful attention to create smooth, flush interior joints.

Troubleshooting Common Construction Issues

Water infiltration represents the most common type of long-term damage. This often results from improper flashing or missing caps.

Multiple flues within one chimney require 4-inch solid masonry partitions. Ensure all vents handle the same type of combustion byproduct.

Address problems immediately during construction rather than covering them up. Taking extra time to correct mistakes ensures your chimney functions safely for generations.

Maintain proper air gaps between flue liners and surrounding masonry. This prevents thermal expansion issues that cause cracks.

Maintaining and Servicing Your Chimney

Your chimney requires regular care to maintain its safety and efficiency throughout the years. Consistent upkeep prevents minor issues from becoming major, costly problems. A simple maintenance routine protects your investment.

Think of this service as an essential health check for your home. It ensures everything functions correctly and safely.

Routine Cleaning and Annual Inspections

Schedule a professional inspection every year. This service is your best defense against hidden hazards. Certified sweeps remove dangerous creosote and debris.

Heavily used systems, like those for stoves, may need bi-annual checks. A thorough cleaning process keeps the flue clear and functional. Early problem detection saves money and ensures safety.

Resealing and Repairing Joints

Water is a chimney’s biggest enemy. Check the seal at the top around the cap regularly. This prevents moisture from entering and causing damage.

High-quality sealant lasts 15-20 years before needing reapplication. Watch for warning signs like moss growth or deteriorating mortar joints. Repairing these joints, called repointing, restores water resistance.

Also, inspect the flashing where the structure meets the roof. Damaged flashing allows water into your home, leading to serious damage. Addressing these issues promptly is crucial for long-term performance.

Conclusion

Successfully building a permanent fixture that serves heating appliances involves balancing aesthetic appeal with functional requirements. This comprehensive guide has walked you through the entire masonry process from foundation to rooftop.

Whether your project involves traditional fireplaces or modern heating systems, proper construction methods ensure safety and efficiency. Attention to details like mortar joints, flue sizing, and water management protects your home investment for years.

This type of work often benefits from professional service, especially when dealing with complex roof areas or heavy materials. Regular maintenance extends your structure’s lifespan dramatically.

Annual inspections catch small issues before they become major problems. Proper cleaning removes dangerous debris that could affect performance.

You now have the knowledge to make informed decisions about your masonry project. This understanding helps ensure reliable, safe operation for your home’s heating needs.

0 Comments